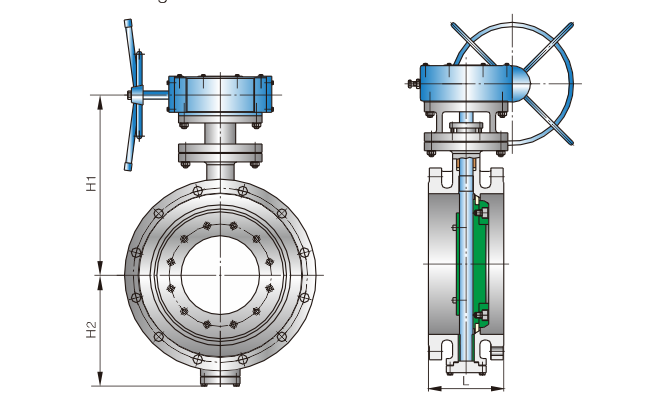

产品特征 Spericfications 适用介质:水、气、油品、天然气和酸碱腐蚀性介质 适用温度:-196~150℃ 驱动方式:手动、气动、电动、液动等 公称压力:0.6~1.6MPa 公称通径:DN50~4500mm Applicable media: water, gas, oil, gas and acid and alkali corrosive medium Applicable temperature: -196~150℃ Driver: manual, pneumatic, electric, hydraulic, etc Nominal pressure: 0.6~1.6MPa Nominal size: DN50~4500mm 产品结构特点 Construction features 本双向蝶阀采取多层次三偏心金属硬密封结构,不仅具有普通多层次三偏心金属硬密封蝶阀的全部优良性能,由于在设计上合理地减小了径向偏心值,在关闭状态下阀杆所受力矩较小,处于静平衡,同时, 蝶板密封圈采用了优质碳素材料与高韧性不锈钢组成多层次结构,不仅柔中有刚能与阀座保持最佳密合,而且具有非常良好的自动补偿功能,特别在较大温差的工况条件下,可以消除由此引起的结构变形对密封性能的影响,又由于在加工和装配过程采用了予应力方法,使阀门在反向受压时产生的相对位移得到充分补偿,因此本蝶阀不论正向或反向受压,均能在全额压差下达到泄漏量为零。 This bi-directional take multi-level triple eccentric metal hard seal structure, not only has ordinary multi-layer all excellent properties of triple eccentric metal hard seal butterfly valve, due to the design reduces the radial eccentricity value reasonably, in closed valve stem torque is small, in static equilibrium, at the same time, the butterfly plate sealing ring with the high quality carbon materials with high toughness of multi-layer stainless steel structure, not only in the soft just can maintain the best closed with the valve seat, and have a very good self-compensation function, especially under the condition of the working condition of large temperature difference, can eliminate the resulting structure deformation influence on sealing performance, and because of adopted to stress during the process of processing andassembling method, makes the valve in the reverse pressure when the relative displacement be compensated fully, either forward or reverse pressure, therefore this butterfly valve are under full differential pressure to achieve zero leakage. 试验压力 Test prssure 技术规范 Technical specification 主要零件和材质 Main parts and materials

压力等级

Pressure grade试验压力 Test pressure 公称压力 PN

Nominal pressure壳体试验

Sheil test正密封试验

Sealing test反密封试验

Sealing test气密封试验

Air seal test0.6 0.9 0.66 - 0.6 1 1.5 1.1 - 0.6 1.6 2.4 1.76 - 0.6 设计依据 Design reference GB系列 GB series 设计标准 Design standard GB/T12238 结构长度 Face to face GB/T12221 连接法兰 End flange GB/T9113 GB/T17241.6 试验和检验 Test & inspection GB/T13927 序号

NO零件名称

Accessor name材质 Material GB系列 1 阀体 Body QT450-10 0.5Cr0.5Ni 2 蝶板 Disc QT450-10 0.5Cr0.5Ni 3 阀座 Seat 堆焊, 13Cr, STL, F316 4 密封圈 Sealing ring EPDM, NBR, PTFE 5 压板 Plate Q235, F304, F316, F316L 6 阀杆 Stem 20Cr13, 304, 316, 316L 7 圆销轴 Taper pin 20Cr13, 304, 316, 316L 8 轴套 Bush bearing 自润滑复合轴套F2 9 填料压盖 Gland WCB, CF8, CF8M 10 填料 Packing 石墨 橡胶 11 螺柱 Bonnet bolt 35#, 304, 316, 316L 12 螺母 Nut 45#, 304, 316, 316L

售后服务免费电话:800-857-7633 联系电话:0577-67317006 67317007 图文传真:0577-67317009

公司总部:浙江省永嘉县东瓯工业园区 邮箱:E-mail:hpv-valve@vip.163.com