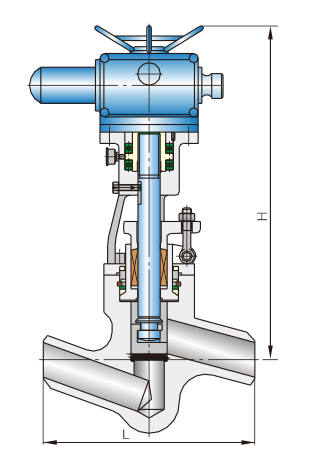

产品结构特点 Construction features 1、产品设计制造按 E101和 JB/T 3595标准的规定,结构合理,性能优良,造型美观。 2、阀门中腔采用压力自紧式密封结构,密封性能好。支管两端为焊接结构,焊接坡口可按标准或用户要求配接。 3、阀瓣、阀座密封面采用司太立(stellite)钴基硬质合金堆焊而成,耐磨、耐高温、抗擦伤性能好、使用寿命长。 4、阀杆经调质和表面氮化处理,有良好的抗腐蚀性和抗擦伤性。 5、阀盖填料函深度合理,填料加缓蚀剂,密封可靠。 6、阀门具有倒密封结构,保证阀门开启运行时,不经阀杆外漏。 7、电动截止阀配有DZW系列阀门电动装置,具有壳体小,重量轻,功能全,外形美等特点,并可与程控电脑配套使用,也可按用户要求选配电动装置。 1. Product design and manufacturing shall be based on E101 and JB/T 3595 standard, with reasonable structure, excellent performance and beautiful appearance. 2. Pressure self-tightening sealing structure is adopted in the valve middle cavity, and the sealing property is good. The two ends of the branch are welded, and the weld groove can be connected by standard or user's request. 3. The disc and seat cover are made of stellite and cobalt base hard alloy, wear resistant, high temperature resistance, good abrasion resistance and long service life. 4. The valve rod is treated with adjustment and surface nitrification. It has good corrosion resistance and abrasion resistance. 5. The valve cover packing function is reasonable, packing and corrosion inhibitor, sealing and reliable. 6. The valve has an inverted seal structure to ensure that the valve opens and runs without the stem leakage. 7, electric cut-off valve is equipped with DZW series valve electric device, with a small shell, light weight, full functions, appearance beautiful wait for a characteristic,and can be used with programmable computer, can also be equipped with electric device according to the requirements of customers. 产品特征 Spericfications 适用介质:水、气、油品、天然气和酸碱腐蚀性介质 适用温度:-196~425℃ 驱动方式:手动、气动、电动等 公称压力:900LB~2500LB 公称通径:2"~10" Applicable media: water, gas, oil, gas and acid and alkali corrosive medium Applicable temperature: -196 ~ 425℃ Driver: manual, pneumatic, electric, etc Nominal pressure: 900LB~2500LB Nominal size: 2"~10" 主要零件和材质 Main parts and materials 技术规范 Technical specification 试验压力 Test prssure 截止阀结构长度和外接尺寸 Main connection dimensions

序号

NO零件名称

Accessor name材质 Material ASTM/API 系列 series 1 阀体 Body A216, WCB, A217(WC6, WC9) 2 浮动座 Floating seat ASTM, A105, A182(F304, F11, F22) 3 密封环 Seal ring 石墨 PTFE, 316L 4 密封垫 Gaskes A182(F304, F11, F22) 5 四合环 Washer ASTM, A105, A182(F11, F22) 6 阀盖 Bonnet ASTM, A105, A182, F304 7 千斤座 Topping bracket A216, WCB, A217, WC6 8 圆锥销 Pin A276(F420, 304) 9 活节螺栓 Bonnet bolt A193, B7, B16, B8, B8M 10 填料 Packing 石墨 PTFE 11 填料压盖 Gland A216, WCB, A217, WC6 12 螺母 Nut A193, B7, B16, B8, B8M 13 支架 Yoke ASTM, A105 14 六角螺母 Nut ASTM, A105 15 内六角螺柱 Bonnet bolt ASTM, A105 16 夹排 Clip line ASTM, A105, A182(F304, F316, F316L) 17 阀瓣 Wedge ASTM, A105, A182(F304, F316, F316L) 18 小阀瓣 Wedge ASTM, A105, A182(F304, F316, F316L) 19 阀瓣盖 Bonnet cap A276(420, 304, 304L, 316, 316L), A182, F11, F22 20 阀杆 Stem A193, B7, B16, B8, B8M 21 螺柱 Bonnet bolt 设计依据 Design reference ASME/API系列 ASME/API series 设计标准 Design standard ASME B16.34 BS 1873 结构长度 Face to face ASME B16.10 连接法兰 End flange ASME B16.25 试验和检验 Test & inspection API 598 压力等级

Pressure grade试验压力 Test pressure 公称压力 PN

Nominal pressure壳体试验

Sheil test正密封试验

Sealing test反密封试验

Sealing test气密封试验

Air seal test900LB 22.5 16.5 16.5 0.6 1500LB 37.5 27.5 27.5 0.6 2500LB 63 46.2 46.2 0.6 900LB 1500LB 2500LB 公称通径

DNL

(mm)H

(mm)L

(mm)H

(mm)L

(mm)H

(mm)2" 368 470 368 540 451 650 2 1/2" 419 560 419 670 508 840 3" 381 685 470 840 578 990 4" 457 830 546 990 673 1210 6" 610 1120 705 1280 914 1470 8" 737 1450 832 1600 1022 1740 10" 838 1960 991 2150

售后服务免费电话:800-857-7633 联系电话:0577-67317006 67317007 图文传真:0577-67317009

公司总部:浙江省永嘉县东瓯工业园区 邮箱:E-mail:hpv-valve@vip.163.com